Electrical Engineering and Computer Science (EECS)

Among the leading departments of its kind in the nation, EECS is creating the technology that puts the “smart” into electronics. Our excellence and impact comes through in the work of our two divisions.

EECS at Michigan

Established. Respected. Making a world of difference. EECS undergraduate and graduate degree programs are considered among the best in the country. Our research activities, which range from the nano- to the systems level, are supported by more than $75M in funding annually — a clear indication of the strength of our programs and our award-winning faculty. With this combination of great resources and talent, EECS at Michigan is transforming and improving a wide range of fields that touch all of our lives.

Tools for “more humane coding”

Prof. Cyrus Omar and PhD student David Moon describe their work to design more intuitive, interactive, and efficient coding environments that can help novices and professionals alike focus on the bigger picture without getting bogged down in bug fixing.

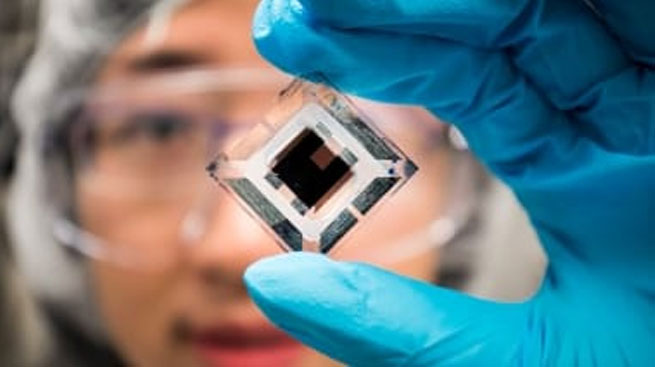

Snail extinction mystery solved using miniature solar sensors

The World’s Smallest Computer, developed by Prof. David Blaauw, helped yield new insights into the survival of a native snail important to Tahitian culture and ecology and to biologists studying evolution, while proving the viability of similar studies of very small animals including insects.

Events

News

CSE celebrates Take Your Child to Work Day with tech-inspired fun

Kids enjoyed more than 10 stations featuring robots, computer-themed crafts, video games, and more.

David Chesney, champion of computing for the greater good, retires

Context matters, and Chesney has demonstrated this for us.

University of Michigan team partners with Semiwise to tackle cryogenic control electronics… technology

Prof. Dennis Sylvester and PhD student Qirui Zhang are working with UK-based company Semiwise Ltd. to design cryogenic circuitry and improve the efficiency of quantum computing.

EECS By the Numbers

Members

Research Expenditures

University

Students, F 2021

MENU

MENU